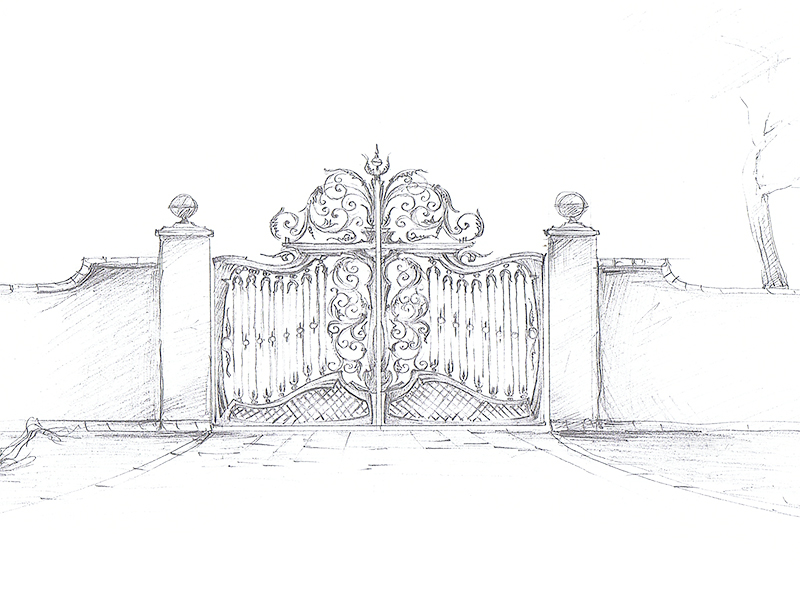

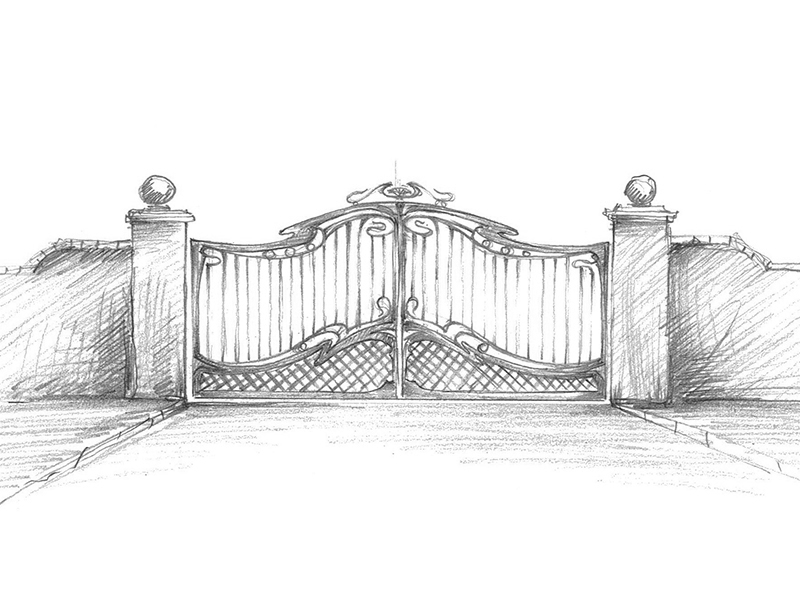

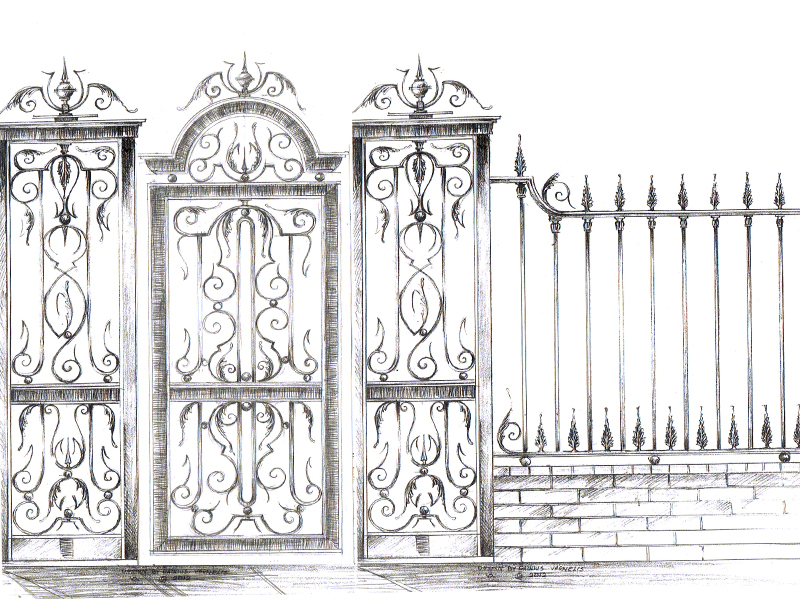

DESIGN INSPIRATION

We have an impressive range of Electric Gates & associated Ironwork should you wish to visit our showrooms with many more designs to view within our Ironwork catalogues and website.

Whilst our designs are purely for inspiration, you may wish to leave them exactly the way they are or perhaps make some alterations to suit your own style. Since all of our gates are made to order, this is no problem.

If you have an idea in mind already, we are happy to discuss your concepts too. We can make just about anything and always welcome a challenge!

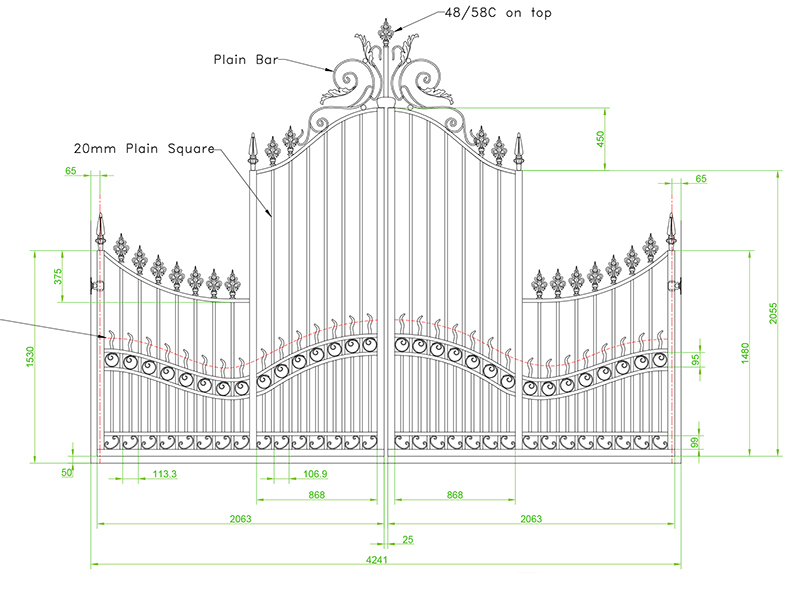

MEASURING

Once we have studied your requirements, we would visit your property to take all the necessary measurements & undertake a full site survey. This isn’t always the case though & dependant on distance we sometimes work from client dimensions & imagery.

From a site meeting or from client imagery, we give expert advice on design, fixing methods & recommend how we would manage such a project.