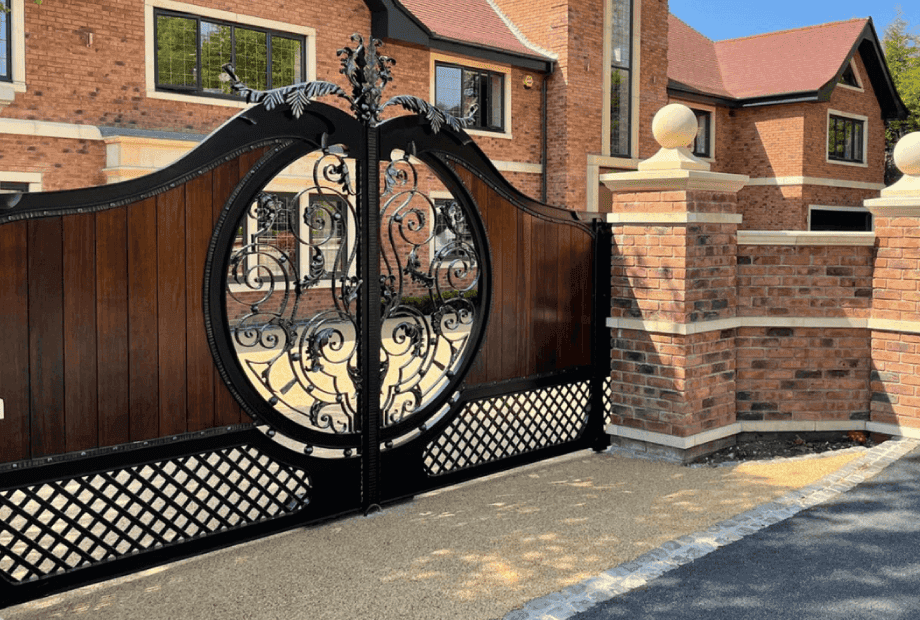

The short version is yes, electric gates work well in snow and ice, but only if you take care of them during the winter months! Snow and ice are notorious for how much disruption they can cause, so obviously the last thing you’ll want is a gate system that won’t function properly when you need it. Wrought iron electric gates like the ones we supply here at North Valley Forge are distinguished by their convenience, security and style – so to keep them performing at their best, it can be helpful to know they respond when the temperature drops and the ground freezes. Here’s what you need to know!

Do snow and ice affect electric gate operation?

Snow and ice can create challenges for electric gates, but these challenges can be managed with the right approach. Both the physical build-up of snow and the freezing of moisture on metal parts can impact the way your gates move and respond, so it can help to know where problems can arise and how to deal with them.

Blocked movement

When snow accumulates in the path of your gates, it can physically block them from moving as they should. Swing gates may not be able to open fully if heavy snow has drifted across the arc of movement, while sliding gates may get stuck if snow builds up along the ground track. Not only does this strain the motors, but it can also put pressure on hinges or rollers. Keeping these paths clear is one of the most important steps you can take to ensure that your gates keep operating smoothly in winter.

Frozen components

Ice can cause moving parts to seize up, especially if any hinges, joints, or rollers are exposed to moisture that later freezes. A frozen hinge or track roller creates friction that slows the gate down, and over time this extra resistance can wear the motor or other components. So, it’s best to lubricate these parts before the coldest months arrive, as it can reduce the risk of ice forming directly on the surfaces and keeps the gates moving freely.

Sensor interference

The sensors fitted to your electric gates are vital for both their safety and performance, and these can occasionally be disrupted by snow or ice. If frost or snow covers an infrared beam, for example, the system may read it as an obstruction and refuse to open or close the gate. In other cases, moisture freezing over the lens can distort the signal. That means it’s a good idea to occasionally check and clean the sensors throughout winter, so that your safety features continue to work as intended.

Motor strain

Gate motors are built to handle daily use, but snow and ice can increase the load they need to overcome. If the gate is trying to push through compacted snow or stiffened joints, that can cause the motor to work harder than usual, which can lead to faster wear or even a breakdown. Many modern motors have built-in obstacle detection to stop the gate when resistance is too strong, which helps protect the system. Still, the less the motor has to fight against snow and ice, the longer it will last.

How to prepare your driveway and gate area for winter

As you might expect, preparation makes a big difference when it comes to keeping your gates working well in snowy or icy conditions. So, the first step is to make sure the area around your gates is kept clear. When snow falls, ideally it helps to clear away drifts from the ground tracks of sliding gates or from the arc of swing gates. This prevents the motors from straining against obstructions. Using a snow shovel or even a stiff broom regularly after heavy falls will keep the paths of movement free and safe. You might also want to think about applying rock salt or grit to the ground near the gates to help prevent ice forming. (This is particularly important on sloped driveways, where ice build-up can be dangerous both for the gates and for vehicles entering or leaving your property.)

Another useful step is to check that your drainage is working properly. If melted snow pools around your gate motors or along the base of the gate, it can refreeze overnight, causing ice to form where it’s most inconvenient. Happily, you can reduce this risk by clearing any leaves or debris from drains before winter arrives. If your motors are above ground, check that the covers are secure and intact so moisture can’t get in. For underground motors, inspect the drainage channels to make sure water isn’t trapped around them.

5 maintenance steps that keep your system reliable in cold weather

Keep all moving parts lubricated with suitable grease or oil. This includes hinges, rollers, and sliding tracks. Lubrication prevents ice from forming directly on the metal and reduces the risk of stiffness or grinding during movement.

Inspect the gate motors regularly for signs of wear or exposure. If you notice any cracks or gaps in the casings, address them immediately so moisture can’t seep in and freeze.

Clean the safety sensors often, especially after snowfall. Wipe away any frost, dirt, or snow that may interfere with the sensors, as this ensures the safety systems work as designed.

Test the obstacle detection system before winter and during cold spells. Place an object in the path to make sure the gate stops when it should. This confirms the safety settings are still working correctly even when the temperature drops.

Schedule a professional service at least once a year before winter sets in. A specialist can check electrical connections, adjust motor settings, and ensure the system is fully protected against seasonal challenges.

In short, looking after the mechanical parts, protecting the motors, keeping sensors clean, and arranging timely servicing reduces the risk of breakdowns. Your gates will continue to provide security, ease of access, and a strong visual presence, however harsh the winter weather becomes.

That’s all the essentials covered! If you’ve got any more specific questions about electric gates that we’ve not answered here, you can always check out our post on troubleshooting for your gates. Alternatively, don’t hesitate to get in touch with our team on 01282 677300. And if you’re considering an electric wrought iron gate and want to learn more about what we can do for you, simply request one of our brochures, make an enquiry, or give us a call.

At North Valley Forge, we’re proud to be one of the premier manufacturers of wrought iron electric gates and railings in the UK. With over 30 years of experience, we’ve been trusted nationwide for our exceptional craftsmanship and reliable installations – so we’ll always be happy to help.

Menu

Menu