Our Process

From drawing board to reality…

We have an impressive range of Electric Gates & associated Ironwork should you wish to visit our showrooms with many more designs to view within our Ironwork catalogues and website.

Design Process

Whilst our designs are purely for inspiration, you may wish to leave them exactly the way they are or perhaps make some alterations to suit your own style. Since all of our gates are made to order, this is no problem.

If you have an idea in mind already, we are happy to discuss your concepts too. We can make just about anything and always welcome a challenge!

Next steps, making your gate come to reality...

Measuring

Once we have studied your requirements, we would visit your property to take all the necessary measurements & undertake a full site survey.

This isn’t always the case though & dependant on distance we sometimes work from client dimensions & imagery.

From a site meeting or from client imagery, we give expert advice on design, fixing methods & recommend how we would manage such a project.

CAD

Following an official order & in receipt of a deposit, one of our experienced CAD engineers will produce Design Drawings for your approval.

Using exact scaled dimensions, you will get a very good idea of how the finished design will look.

Once the drawings are approved these are sent to our fabrication department to be made.

Fabrication

All of our ironwork is manufactured at our main Factory & Headquarters in Nelson, Lancashire using a combination of age old blacksmithing techniques and modern machinery. Our craftsmanship and attention to detail is evident in every aspect of our work and we ensure that our quality is always consistent.

Hot Dip Galvanising

Hot-dipped galvanizing is a process of coating mild steel by immersing the fabricated product in a bath of molten zinc at a temperature of around 900 °F. This involves chemically cleaning prior to dipping to remove any substrates & once completed, the zinc coating is fully bonded to the Ironwork. This guarantees the longest possible lifetime for anything metal affected by outside elements, such as rain, frost or snow, along with the least maintenance also.

Powder Coating

All our ironwork is powder coated as standard in our state-of-the-art facility. Our standard finishes are black or anthracite grey, however, we can powder coat to any specified RAL to achieve your perfect finish.

One of the primary benefits of powder coating is its durability. The coating is highly resistant to scratches, chips, and fading, making it an ideal choice for outdoor applications or products that are exposed to harsh environments. Powder coating also provides a more even and consistent finish, eliminating the need for touch-ups or reapplication.

Our ironwork is made to last, meaning no maintenance for years to come!

Finishing

Our metal gates and railings can be given a variety of finishes after painting including patinas. As standard we use gold, silver & bronze brushed very lightly over the contours to highlight the detail in the work, bringing the design to life.

Alternatively, ironwork can be left with a plain painted finish or for the more extravagant option we have Everlasting Gold paint which certain details such as Railheads, Bushes, Cages etc. It can be painted fully to give that Midas Touch. Our Hardwood gates are finished using UV protective coatings, which not only shield the wood from fading, but also enriches the natural grain and beauty, achieving a glossy sheen.

Installation

Leave the hard work to us – from groundworks to installing intercom systems; we offer an end-to-end installation service. The only requirement we have is a power supply for electric gates and we can do the rest.

We install ironwork across the UK using our experienced, in-house team. No matter the difficulty of the project, we always have a solution to ensure a seamless finish.

Safety

When installing automation a range of safety tests need to be carried out including force testing and CE marking before we leave site. All of this will be explained to you when you place your order including information regarding the amount of safety edges and photocells you will need for your gate type.

Rest assured that we only ever install automation systems that are safe and reliable as not only do we have over 30 years’ experience in this field, we are accredited members of Gate Safe and DHF.

Aftercare

If you have chosen to have your gates automated; once all relevant safety tests have been carried out by the engineer you will receive a ‘Handover Pack’ including all site risk assessment information and documentation including the testing procedure.

You also receive a 12 month parts and labour warranty from the completion date on installed automation and access control systems.

Servicing is optional although we do highly recommend that you have your gates serviced annually. We have both Gold & Silver service

plans which can be explained to you.

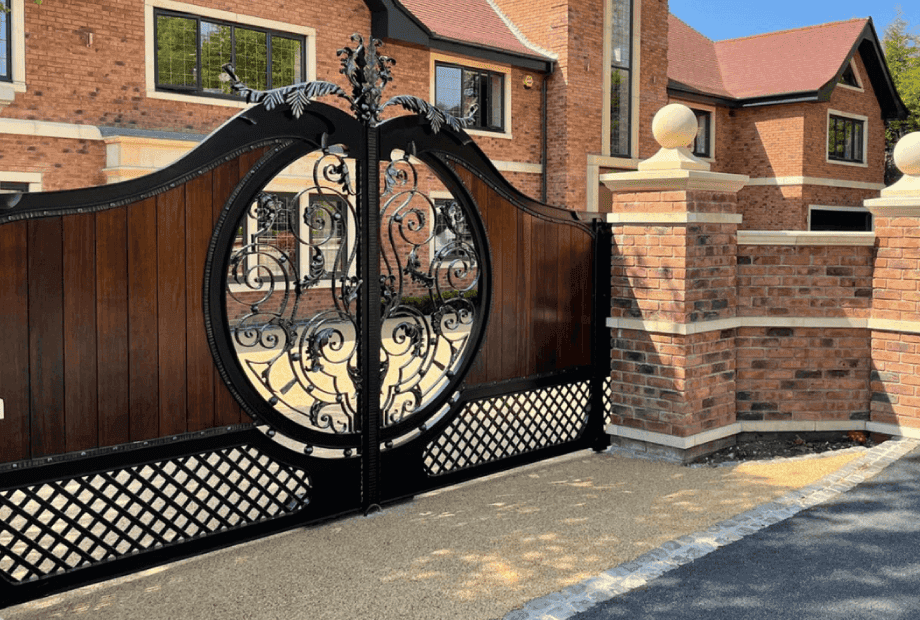

The Only Limit is your Imagination

Say hello to the Radleigh! Part of our Estate Gate Collection, this gate is all about blending timeless elegance with wow factor!💫 From gothic fleur de lys railheads to its ornate arches and decorative details, every inch of the Radleigh is designed to impress. It`s fully customisable too - because your gate should be as unique as your style. Finished in a black powder coat with a patina of your choice; it`s not just a gate - it`s a masterpiece that adds beauty and security to your home!

📞01282 677 300

📩sales@northvalleyforge.co.uk

🌐www.northvalleyforge.co.uk

#NorthValleyForge #homesecurity #BespokeDesigns #HomeImprovement #AutomatedGate #ElectricGate #service #fabrication #luxuryhome #luxuryrealestate #LuxuryLiving #Luxury #luxurydesign #Automation #installation #homeinspo #irongates #wroughtiron #manufactured #welding #drivewaygate #gates

Introducing our Latest Install: A Side Gate with Aluminium Infill🌟

This stunning gate combines sleek, contemporary design with practical functionality. Featuring a grid pattern on both the top and bottom sections, the centerpiece is an aluminum infill designed to mimic the natural beauty of wood - giving it a modern yet warm feel. Finished in a black powder coat, the gate is not only stunning but built to last. We`ve also added a Locinox door handle for a smooth and secure finish.

This side gate is proof that modern design can be both eye-catching and functional✨💫

📞01282 677 300

📩sales@northvalleyforge.co.uk

🌐www.northvalleyforge.co.uk

#NorthValleyForge #homesecurity #BespokeDesigns #service #fabrication #luxuryhome #luxuryrealestate #LuxuryLiving #Luxury #luxurydesign #installation #homeinspo #irongates #newinstall #wroughtiron #manufactured #welding #gates

Introducing our Latest Install: Balustrade with Composite Infill✨

This sleek and modern balustrade features birch grey composite infill, complemented by decorative wrought iron circles for added detailing. The black powder-coated ironwork ties it all together for a stylish durable finish, that`s perfect for this balcony.

Stay tuned for the full reveal - we can`t wait to show you the finished project! ⚒️✨

📞01282 677 300

📩sales@northvalleyforge.co.uk

🌐www.northvalleyforge.co.uk

#NorthValleyForge #CompositeGate #BespokeDesigns #IronRailings #GardenRailings #service #fabrication #luxuryhome #luxuryrealestate #LuxuryLiving #Luxury #luxurydesign #homeinspo #newinstall #wroughtiron #manufactured #railings

Introducing our Latest Install: The Composite Orpheus Gate💫

Leveled up with birch grey composite infill for ultimate privacy! Composite is not just a smart choice - it`s weather resistant, super low maintenance, and built to last, so you get all the good looks without the hassle.

The gate doesn`t stop there - at the top, you`ve got stunning scrollwork with a silver patina finish that really brings out the intricate details, giving it that extra `wow` factor. To make it even more special there`s a custom name plate and bespoke decorative handles that add a charming, personal touch. Powder coated in black, this gate is the perfect blend of style privacy, style and durability✨🌟💫

📞01282 677 300

📩sales@northvalleyforge.co.uk

🌐www.northvalleyforge.co.uk

#NorthValleyForge #AutomatedGate #HomeImprovement #CompositeGate #BespokeDesigns #homesecurity #IronRailings #ElectricGate #fabrication #luxuryhome #luxuryrealestate #LuxuryLiving #Luxury #luxurydesign #installation #homeinspo #irongates #newinstall #wroughtiron #manufactured #welding #drivewaygate #railings #gates

🚪💫Side Gates, But Make It Ultimate!💫🚪

Looking for a side gate that`s anything but ordinary? Our Ultimate Collection has you covered. Whether you want something to match your driveway gate or a stand-out piece that makes a statement, these gates are all about style, durability, and security.

Fully customisable in any colour or finish (yes, any), with stunning scrollwork or sleek modern designs, the possibilities are endless. Crafted with the same attention to detail as our driveway gates, these side gates don`t just look amazing - they`re built to last.

Ready to create the perfect side gate for your home? Let`s make it happen!🌟

📞01282 677 300

📩sales@northvalleyforge.co.uk

🌐www.northvalleyforge.co.uk

#NorthValleyForge #homesecurity #BespokeDesigns #HomeImprovement #AutomatedGate #CompositeGate #IronRailings #GardenRailings #ElectricGate #service #fabrication #luxuryhome #luxuryrealestate #LuxuryLiving #Luxury #luxurydesign #installation #homeinspo #irongates #wroughtiron #manufactured #drivewaygate #railings #gates

Menu

Menu