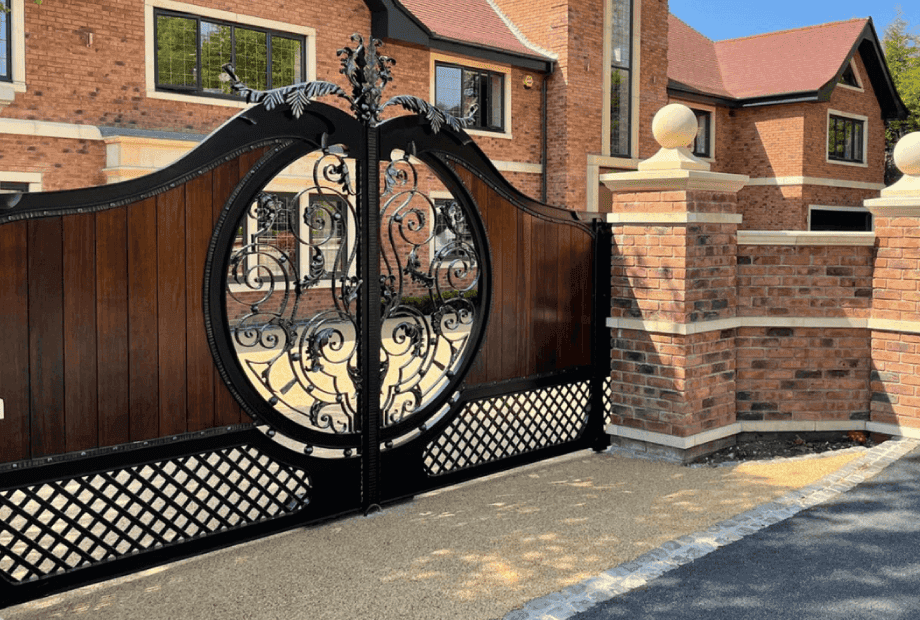

At North Valley Forge, we understand that choosing the perfect wrought iron gate for your property is about more than just aesthetics. It’s an investment in the safety, style, and lasting appeal of your home. For over 30 years, we’ve been handcrafting bespoke electric driveway gates using time-honoured blacksmithing techniques passed down through generations of skilled artisans.

One of the questions we hear most often is whether galvanising is essential when commissioning a gate. The short answer? No, you don’t have to have your gate galvanised. We can create your gate exactly how you want it, from raw steel finishes to fully galvanised and powder-coated masterpieces. However, it’s important to understand what galvanising does, how it protects your gate, and why it’s a service we highly recommend to all our customers who want their gates to last for decades.

What is galvanisation and how does it protect your gate?

Galvanisation is essentially a way of protecting your luxury electric gates by coating it with a layer of zinc. This zinc layer acts like a shield, keeping your gate from rusting and corroding. At North Valley Forge, we use a method called hot-dip galvanising, which meets the highest British standards for quality and durability.

Here’s how it works: first, we give your steel gates a thorough clean to get rid of any dirt, oils, or grime, making sure the surface is nice and smooth. Then, the gate gets dipped into super-hot molten zinc (about 449 degrees Celsius). This hot zinc sticks to the steel and forms a tough, seamless coating that seals out moisture and oxygen – the two main things that cause rust.

After galvanising, we add a powder coating. This isn’t just for looks (though it does make your gate look amazing); it also adds an extra layer of protection against the weather. So whether it’s rain, frost, pollution, or sun, your gate is ready to take it all.

What happens if you don’t galvanise your hate?

Steel is the material we use to craft what most people call electric wrought iron gates. It’s incredibly strong and built to last, but like all steel exposed to the weather, it will eventually start to rust. Rust usually begins as small patches on the surface, but over time, it can spread and weaken the gate’s structure, affecting both how safe it is and how it looks.

That’s exactly why we galvanise our electric gate ranges – to give them a tough, protective layer that stops rust from taking hold. It’s this process that helps our gates last so long and look great for decades. You can absolutely choose not to galvanise your gate if you prefer, but keep in mind it will need a lot more upkeep like regular repainting, cleaning, and repairs to manage rust and keep it looking its best and even still, it won’t last as long as a galvanised gate.

At North Valley Forge, we combine traditional craftsmanship with modern protective techniques like galvanising and powder coating to make sure your bespoke electric gate is both beautiful and built to last. You don’t have to galvanise your gate, but choosing to do so means investing in enhanced longevity and peace of mind. If you want a gate that’s a set-and-forget feature, one that will keep impressing for decades, galvanising is the best choice. If you have any questions about galvanising, our process or want to explore our electric gate options, just give our expert team a call on 01282 677 300. We’re here to help you create the perfect entrance for your home!

Menu

Menu