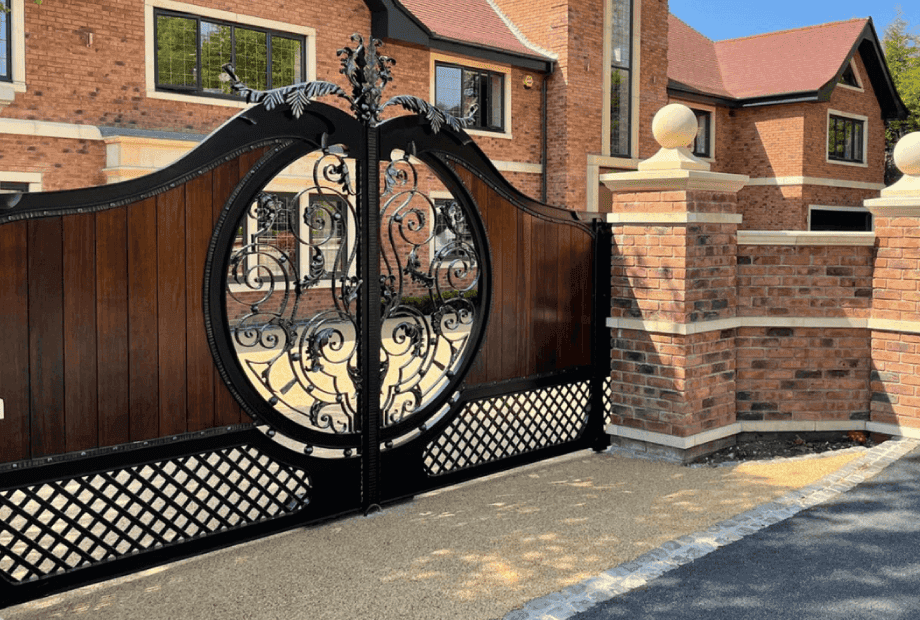

With more than 30 years of experience behind us here at North Valley Forge, we know exactly how valuable electric wrought iron gates are when it comes to both security and style on your property. Now, we obviously make sure to design durability and longevity into them from the start, but like any piece of equipment that combines mechanical parts with electrical systems, they tend to perform best with regular servicing. That’s why it can be so helpful to set up a maintenance schedule – it ensures that your gates can keep moving smoothly, avoid breakdowns, and last longer.

So, when you’re putting yours together, one of your first questions is naturally going to be: how often should they be serviced?

The best standard service schedules for electric gates

At a glance:

- Residential gates: every 12 months

- High-traffic commercial gates: every 6 months

- Gates exposed to harsh weather or roadside dust: every 6 months

In more detail:

In a typical residential setting, you’ll need to arrange servicing for your electric gates at least once every twelve months. This basically ensures that the moving parts and electrical systems remain reliable, as a baseline requirement. In commercial environments on the other hand, your gates may be in more constant use. This level of traffic places heavier strain on the hinges, motors, sensors, and control systems, so you’ll need to consider scheduling every six months.

Seasonal and environmental conditions will also affect how often you’ll need to book servicing. Gates that are exposed to frost, rain, or strong winds tend to risk faster deterioration, and those near busy roads are often faced with dust and debris that can clog mechanisms. So, it’s always worth matching your servicing schedule to the environment, as it help maintain maximum reliability and reduce the chance of unexpected failures.

5 benefits of regular servicing for your property

Regular servicing of your electric gates enables you to enjoy a variety of advantages, both in terms of security and long-term reliability. Each service gives you peace of mind that your gates are performing as they should, while also protecting your property from problems that build up quietly over time.

Improved security

A well-maintained set of gates will respond quickly and consistently whenever you need them to. Servicing makes sure the motors, control boards, and safety systems are operating properly so there’s no risk of the gates sticking open or failing to lock. That means stronger protection for your property day and night, with reliable operation no matter how often the gates are used.

Enhanced safety

Servicing always includes checks of photocells, pressure edges, and emergency stop features. These are designed to keep people, pets, and vehicles safe when the gates are in use. That lowers the chance of accidents and ensures that your gates remain compliant with regulations. It also gives you confidence that the gates won’t create hazards during daily use or in busy environments where multiple people pass through.

Saving money over time

Regular inspections allow engineers to spot small issues before they turn into major failures. Worn parts can be replaced cheaply, electrical faults can be corrected early, and lubrication of moving parts can extend the life of the mechanisms. You can save money over time by avoiding sudden breakdowns that require costly repairs, and keeping the system running efficiently without wasting energy or forcing the motor to work harder than necessary.

Protecting appearance

Wrought iron gates are often chosen for their style as well as their strength, and servicing helps you preserve both. Engineers can treat signs of rust, advise on fresh paintwork, and clean away debris that causes surface damage. This care ensures that your gates remain a feature that adds character to your property and keeps their smart appearance intact for years to come.

Boosting property value

Well-maintained electric gates can add to the value of your home or business premises, largely because prospective buyers and tenants can see that the gates are kept in top condition and that the property has been properly cared for. Servicing records also provide evidence of maintenance, which reassures future owners about the reliability of the system and can give an even stronger impression of the property overall.

What happens during a service appointment?

During a typical service appointment, a trained engineer will check both the mechanical and electrical systems of your gates. On the mechanical side, this may include examining hinges, brackets, arms, and rollers for wear. Lubrication will often be applied where needed to prevent stiffness or grinding. The alignment of the gates will also be tested to make sure they close correctly and don’t strain the motor.

On the electrical side, the engineer will then test the control board, remotes, and wiring for faults or deterioration. Safety features such as photocells, pressure sensors, and manual release mechanisms will be inspected and confirmed as operational. Motor performance may also be measured to ensure smooth opening and closing. All that will provide you with a clear overview of your gates’ condition and highlight potential repairs before they become urgent. As you may know already, preventative maintenance is always better than reactive!

4 signs your gates may need attention sooner

There are times when you may need to arrange servicing before your scheduled appointment. Some of the most common signs include:

- Unusual noises such as grinding, squeaking, or knocking

- Slower opening or closing speeds

- Controls that don’t always respond

- Visible damage such as rust or broken welds

Each of these issues can signal early problems with your gates, so it’s worth addressing them quickly! So, to kick off with: any noises that grow louder with time may mean that some parts are wearing down or the motor is under stress, and so it’s important not to ignore them – otherwise, that risks more serious faults developing. Slower movement is another sign, often caused by strain from misalignment or weakening in the motor.

Other warning signs can be harder to notice at first but become clear if you know what to look out for. Jerky or uneven movement often means one side of the gate is under more pressure than the other, which risks bending components or creating lasting misalignment. You might also see the gates stop mid-cycle or reverse direction unexpectedly, which can point to faults in safety sensors or interference within the control system. Rust patches and cracks in welds spoil the appearance of wrought iron and also threaten the strength of the gates, which makes it essential to service them quickly, preventing further damage.

That’s all the essentials covered! If you’ve got any more specific questions about electric gate servicing that we’ve not answered here, you might want to check out our post on the most common problems that can sometimes occur.

Alternatively, don’t hesitate to get in touch with our team on 01282 677300. And if you’re considering an electric wrought iron gate and want to learn more about what we can do for you, simply request one of our brochures, make an enquiry, or give us a call.

At North Valley Forge, we’re proud to be one of the premier manufacturers of wrought iron electric gates and railings in the UK. With over 30 years of experience, we’ve been trusted nationwide for our exceptional craftsmanship and reliable installations – so we’ll always be happy to help.

Menu

Menu