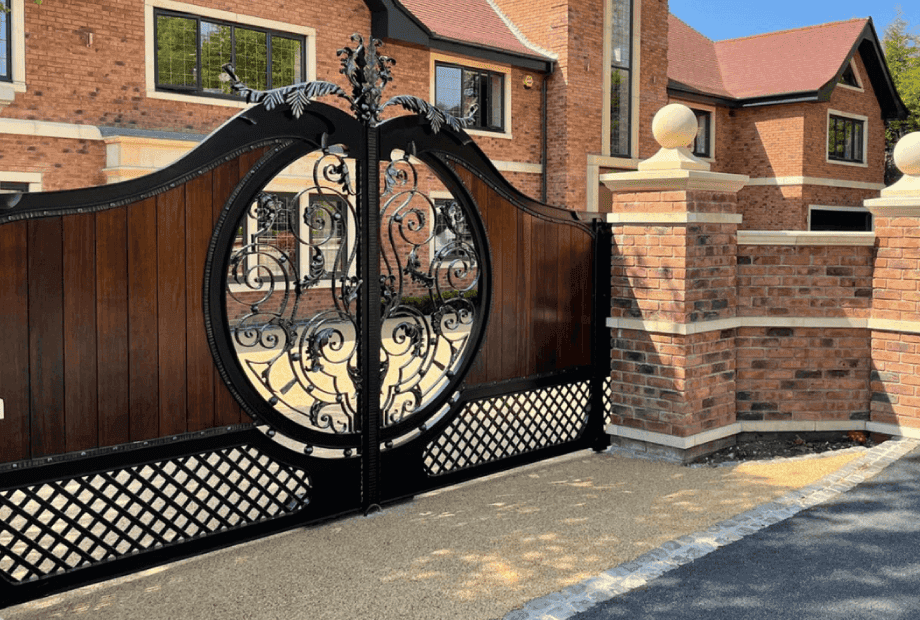

Here at North Valley Forge we take pride in designing and manufacturing our wrought iron electric gates to provide exceptional durability, longevity and performance. That doesn’t make them immune to gradual wear and tear though, and while you can generally count on their components to last a long time (especially with diligent maintenance), eventually they may well need replacing. That obviously includes the motor that powers it. And since the motor is the core element that enables the gate to smoothly open and close, its performance directly affects how secure and convenient your entrance feels. So, how long can you expect it to go for?

How long an electric gate motor usually lasts

An electric gate motor is built to withstand frequent use, weather exposure, and the strain of moving heavy wrought iron gates. Most motors last between 10 and 15 years when you use them under normal residential or commercial conditions. As we touched on above, your motor’s lifespan depends heavily on how many “cycles” it goes through – in other words, how often you open and close the gate each day. Equally, it depends on how well you keep up with routine care. A household that opens the gate four or five times a day will usually see the motor last longer than a busy commercial property where the gates move dozens of times each day.

You can also expect the motor to last longer if you keep an eye on its general condition. Checking for dirt build-up, signs of corrosion, and ensuring the housing is intact are all things that can make a big difference. A well-installed motor that operates within its rated capacity is less likely to burn out early. And don’t forget, while lifespan figures give you a guideline, it’s always best to treat them as averages rather than guaranteed timelines, as your own motor’s condition will be shaped by how it’s used and maintained.

4 factors that affect motor lifespan

There are several different elements that tend to influence the expected lifespan of your electric gate motors. We’ve rounded up four of the most influential ones below.

Usage frequency

It makes sense to start with the obvious! The frequency with which your gate opens and closes has a major impact on the motor’s lifespan. A gate for a residential property will generally have much fewer cycles to go through each day, and therefore it’ll place much less strain on the motor compared to a business, where the gate is more likely to be in constant operation. Each movement adds to the wear of internal components, so higher frequency shortens the time before parts begin to weaken. If you know your gate is (or will be) in regular use, you may want to plan for shorter replacement intervals to keep everything running smoothly.

Gate weight

The size and weight of your wrought iron gate can also play a significant role in how much work the motor has to do. A large, heavy gate requires generally more power each time it moves, which can gradually wear down the motor. However, we should point out that it’s not something to worry about too much, as heavier gates will generally be supplied with stronger motors to offset this extra weight accordingly.

Environmental exposure

Your motor’s environment affects how well it copes over the years. Rain, frost, wind-blown dust, and strong temperature changes – they’re all factors that can gradually contribute to wear and tear. Moisture can cause corrosion inside the housing, while fine grit can build up in moving parts and cause resistance. Happily, a motor with proper weatherproofing, securely fitted housing, and regular cleaning will withstand these pressures far better – so we make sure to take it into account when we supply yours here at North Valley Forge.

Quality of installation and servicing

Finally, the way in which your motor is installed and maintained often directly affects its longevity, which is one of the reasons we pay so much attention to it at North Valley Forge. An experienced technician can ensure the proper alignment and correct power supply for your gate, both of which reduce any unnecessary stress. Regular servicing also adds another layer of protection, as small adjustments and timely part replacements can stop larger failures from developing.

How to maintain your motor to extend its life

As we’ve just touched on above, one of the best ways to extend the life of your motor is by carrying out regular checks and maintenance. That includes cleaning around the motor housing to remove leaves, dust, and other debris to prevent blockages and reduce wear, and lubricating moving parts like hinges to ease the pressure on the motor, and ensure the gate opens smoothly.

You’ll also benefit from arranging professional servicing at least once a year, which is a service that we provide here at North Valley Forge. A technician can check for loose connections, test the motor output, and make adjustments that stop small problems from developing into major ones. Oh, and finally, using a surge protector is another useful step, as power surges and electrical issues can also pose the risk of damage to your gates.

That’s all the essentials covered! If you’ve got any more specific questions about electric gate servicing that we’ve not answered here, don’t hesitate to get in touch with our team on 01282 677300. And if you’re considering an electric wrought iron gate and want to learn more about what we can do for you, simply request one of our brochures, make an enquiry, or give us a call.

At North Valley Forge, we’re proud to be one of the premier manufacturers of wrought iron electric gates and railings in the UK. With over 30 years of experience, we’ve been trusted nationwide for our exceptional craftsmanship and reliable installations – so we’ll always be happy to help.

Menu

Menu