One of the most common questions we hear at North Valley Forge is, “how long will my metal gates last?” It’s a valid question, but there isn’t a one-size-fits-all answer. The good news is that with the proper care and maintenance, you can expect your gates and railings to last for decades.

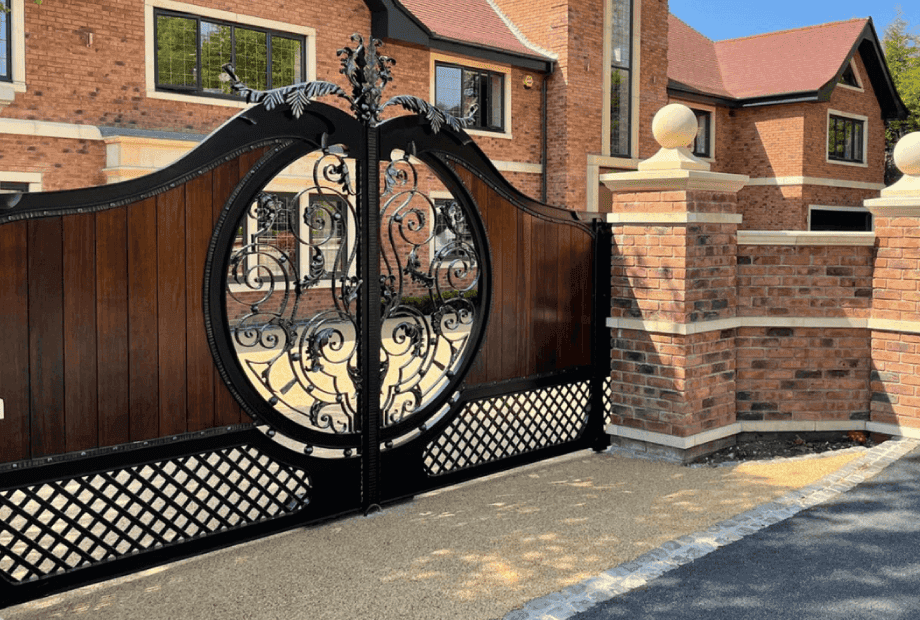

At North Valley Forge, we take pride in our expertise in crafting bespoke wrought iron and electric gates. Our bespoke gates are built to endure, thanks to our skilled artisans who blend traditional blacksmithing techniques with modern approaches. We understand that longevity is essential because your gate is more than just a structure; it’s an investment. That’s why we put in extra effort to ensure your gate will stand the test of time.

The longevity of your gate

So, the question is, how long will your gate last? Well, the short answer is that well-maintained galvanised gates can last 30 years or even longer! This lengthy time frame is one of the reasons why so many of our customers choose us to create their gates.

The longer version is that it’s subject to a few variables. Environmental conditions like high humidity, salty air, or exposure to chemicals can cause the galvanised layer of your gate to wear down over time. While this doesn’t necessarily happen quickly, if you live near the coast, for example, your gate may show signs of corrosion sooner than if you live in a more rural area. This is because salts and pollutants can react with the zinc coating, which allows the rust to start to form. That’s why maintenance is so important. If the galvanised coating becomes too thin or isn’t cared for properly, the metal underneath can start to rust.

Caring for your electric gates

While metal gates are generally far more durable than wooden ones, they still require some attention, especially if they’re electric. For all gates, check for signs of dirt or damage and clean the surface with a cloth to remove debris and moisture that could speed up the corrosion process. For more thorough cleaning, use warm, soapy water and a soft bristle brush as and when needed to give them a good scrub – just be sure to wash off all the soap after you’re done.

If your gate is automated, regularly check and clear debris from sensors and tracks to keep the gate moving smoothly. You’ll also need to lubricate moving parts such as hinges, wheels, and motors as and when they need it to reduce wear and tear. Finally, keep an eye on the motor and electrical components of your automated gates. We can provide a professional service if your electric gates ever need it.

Galvanisation and powder coating for durability

Our gates are designed for long-lasting strength and resilience, using techniques like galvanisation and powder coating for optimal protection. Galvanisation coats the metal with a layer of zinc, which helps prevent rust and corrosion and allows the gates to withstand various weather conditions. We follow British Standard EN ISO 1461 and use the hot-dipping method, where the steel is submerged in molten zinc at 449°C, ensuring a strong, durable coating.

Once the galvanisation process is complete, we apply a powder coating. This step not only adds an extra layer of protection but also enhances the appearance of the gates. The powder coating reduces the need for ongoing maintenance, keeping your gates looking great!

The fact they can last over 30 years makes them a worthy investment if you’ve been considering them! At North Valley Forge, we combine traditional craftsmanship with modern techniques to create gates that stand the test of time. From galvanisation and powder coating to regular upkeep, we make sure your electric wrought iron gates are built to last, offering you peace of mind and a lasting investment. With a bit of attention, your gates will continue to serve you well, enhancing your property for decades. If you have any questions on any of the topics we covered above, don’t hesitate to reach out to our team today on 01282 677 300. We’re here to help!

Menu

Menu