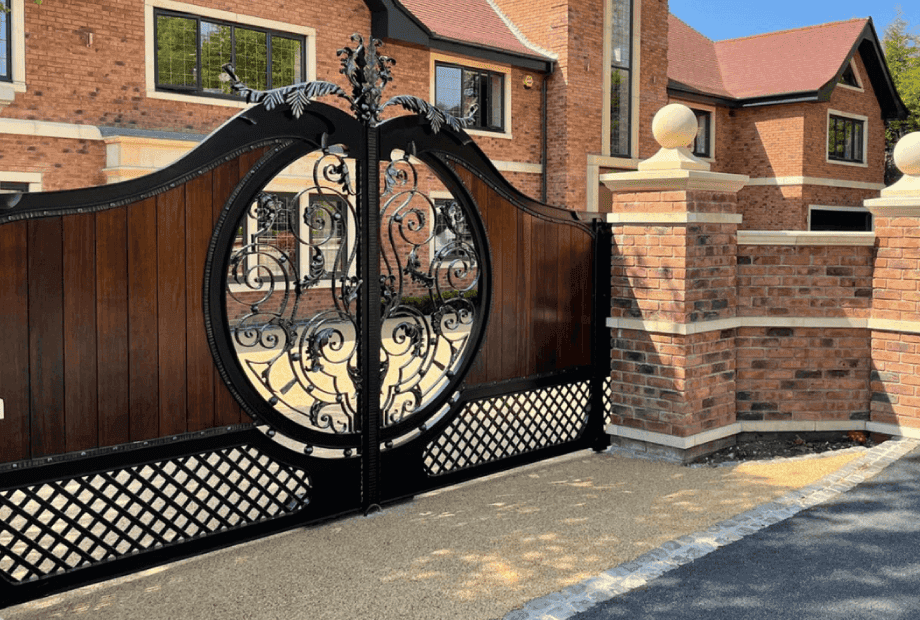

Wrought iron electric gates are perfect for enhancing your property with an extra layer of convenience and security, and like most home additions, they work best when they’re properly maintained. Happily, even on the rare occasion they develop faults, most are still quite straightforward to sort out. We have more than 30 years of supplying these gates here at North Valley Forge, so you can count on our team to know about some of the most common issues that sometimes pop up – and what you can do about them.

The gate motor isn’t responding

If your gate motor isn’t responding when you try to open or close the gate, the first thing to do is to check is the power supply. Make sure the gate is plugged in and the circuit breaker or fuse hasn’t tripped. Sometimes a loose connection or a blown fuse can stop the motor from receiving power altogether. Also, inspect any visible wiring to see if cables have become loose or damaged. You can use a multimeter to test if power is reaching the motor terminals, but if you’re unsure, the safest choice is probably getting a qualified electrician to check the supply.

Next, look at the motor itself for signs of overheating or physical damage. Motors that have been working hard for a long time may overheat and shut down temporarily. If the motor feels very hot, allow it to cool down before trying again. You might also want to inspect the control board, which manages the motor’s commands. A faulty control board can stop the motor from running even if power is present. Sometimes resetting the system by switching the power off for a few minutes can clear minor faults. If the motor still doesn’t respond after these steps, it might require professional servicing, or possibly replacement.

The gate stops or reverses unexpectedly

When your gate stops or reverses direction without warning, the cause of that can often be traced back to safety sensors. These sensors detect obstacles in the gate’s path and trigger a stop or reversal to prevent damage or injury. Check if anything is blocking the sensors, such as leaves, dirt, or debris. Sensors can also become misaligned over time due to weather or accidental knocks, so gently clean them and make sure they face each other correctly.

Apart from sensors, examine the gate track for any obstructions or damage. Small stones, branches, or worn-out rollers can interrupt smooth movement and cause the gate to stop suddenly. Automatic reverse features rely on limit switches that tell the gate when to stop moving in a particular direction, so take a look at these switches to ensure they haven’t shifted or broken. It might just be a case of adjusting the switches back into their proper positions, or replacing damaged ones, which can resolve unexpected stops or reversals.

Remote control issues

If your gate remote isn’t working, start by checking the battery. Batteries lose power over time, and a weak battery often causes inconsistent or no response from the gate. Replace the battery with a fresh one designed for your remote model. If the remote still fails to operate the gate, try reprogramming or resyncing it with the gate control system. Instructions for this usually come with your gate or remote manual, or a professional installer can assist.

Signal interference can also affect remote performance. Look for sources of interference nearby, such as strong radio signals, other wireless devices, or metal structures that block or weaken the remote’s signal. If the receiver unit on the gate itself is faulty or damaged, the remote won’t be able to communicate properly. Inspect the receiver for signs of wear, corrosion, or damage and have a specialist repair or replace it if necessary.

The gate moves slowly or gets stuck

A gate that moves slowly or jams can be hugely frustrating, especially since it may be putting extra strain on the motor. One of the best places to start is by lubricating all moving parts, including hinges, rollers, and tracks, with a lubricant suitable for metal components. Lack of lubrication causes friction, which slows the gate and can eventually stop it. Be careful to avoid over-lubricating – somewhat counter-intuitively, this can attract dust and grime, making the problem worse.

Here’s a big one – you’ll also need to check for any obstacles blocking the gate’s movement path, such as stones, branches, or rubbish. It can end up being the cause of the problem far more often than people think, and could save you a potentially expensive callout.

If that’s not sorted it, inspect the motor’s gears and mechanical components for wear or damage. Gears that have worn down or broken can reduce the gate’s speed or cause it to seize. Finally, verify that the gate is aligned correctly and balanced. If the gate has shifted out of alignment due to ground movement or impact, it will struggle to move smoothly and may get stuck at points along the track. If that’s the case, realigning the gate and adjusting its balance can ensure that it ends up working properly again.

That’s all the essentials covered! If you’ve got any more specific questions about electric gates that we’ve not answered here, don’t hesitate to get in touch with our team on 01282 677300. And if you’re considering an electric wrought iron gate and want to learn more about what we can do for you, simply request one of our brochures, make an enquiry, or give us a call.

At North Valley Forge, we’re proud to be one of the premier manufacturers of wrought iron electric gates and railings in the UK. With over 30 years of experience, we’ve been trusted nationwide for our exceptional craftsmanship and reliable installations – so we’ll always be happy to help.

Menu

Menu