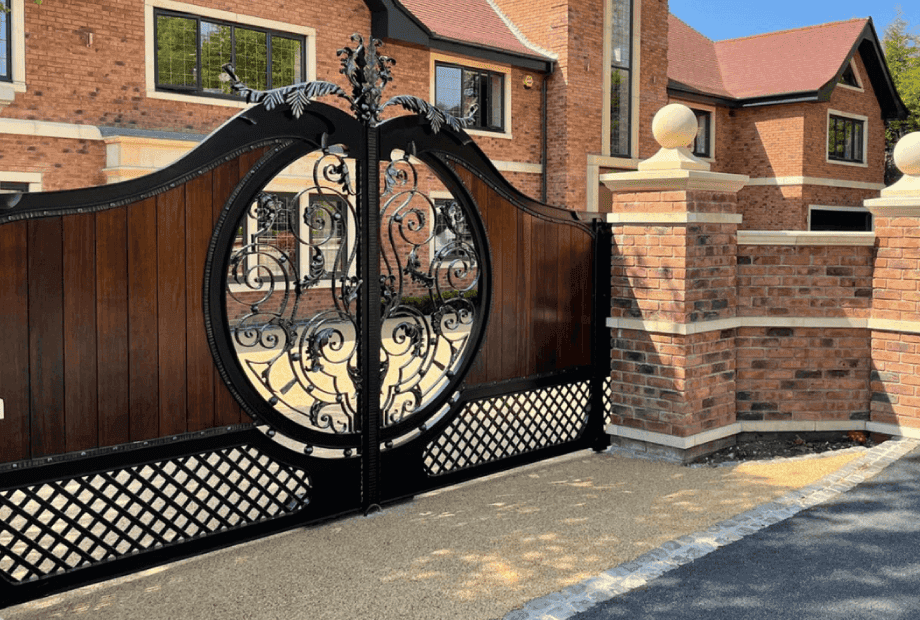

Wrought iron gates remain a favourite choice across the UK – and it’s no wonder why! We have a great range of wrought iron gates to choose from ourselves here at North Valley Forge, so you’ll always be able to find an option perfectly suited to your property.

Now, one of the first decisions that you’ll need to make is of course to do with the actual mechanism of your gates. For lots of our customers, that’s often a choice between sliding and cantilever gates, both of which are known for their efficiency and space-saving designs. Each option offers unique strengths depending on the space available, the terrain, and how frequently the gate will be used.

So, if you need a quick primer, here’s what you need to know. Let’s start with sliding gates!

An overview of sliding gates and their benefits

At a glance:

- Moves horizontally along a ground track

- Ideal for sites with limited internal space

- Track requires regular clearing and maintenance

- Suits level ground with firm surfaces

- Compatible with automation and access systems

- Provides strong security and a sleek appearance

Sliding gates operate on a track laid into the ground, enabling the gate to glide horizontally across the entrance. A typical configuration involves a single gate leaf that moves to one side, often powered by an electric motor. The track needs to be kept clear of debris and regularly maintained to ensure smooth operation, especially in outdoor settings where leaves, stones or snow might accumulate. For maximum reliability, they’ll also need routine cleaning and periodic inspections of the wheels and motor.

These gates are particularly beneficial where space behind the gate might be limited. Unlike swing gates, which require a broad arc to open inward or outward, sliding gates tuck neatly along a wall or fence line, making them suitable for narrow driveways or any other properties that might need to maximise their usable space is important. Their lateral movement also means they don’t encroach on footpaths or internal driveways, enabling better flow of cars and pedestrians.

They’re also highly secure. The full-length track and locking mechanism provide a strong resistance to forced entry. Plus, their sleek, linear motion gives them a contemporary appearance that suits modern architectural styles. And because the gate’s weight is supported along the entire track, larger or heavier gates can be installed without placing excessive strain on the structure. This makes them a versatile choice for everything from small residential entrances to wide industrial compounds.

An introduction to cantilever gates and their main advantages

At a glance:

- Suspended design with no ground track

- Ideal for uneven or obstructed surfaces

- Requires extended lateral space for support

- Lower maintenance in challenging environments

- Suits heavy-duty and wide-span installations

- Commonly used in commercial or industrial settings

Cantilever gates function differently by hanging above the ground, supported by a system of rollers attached to a vertical post or support structure. Instead of sliding along a track, the gate is suspended in the air and moves across the opening from one side. This design removes the need for anything to be embedded in the ground across the gateway. It’s a free-floating motion, and lots of customers perceive it as more elegant in its glide, and less susceptible to external interference.

This makes cantilever gates a strong choice in areas where the ground is uneven, sloped, or frequently obstructed. Gravel paths, snow-prone regions, or commercial yards with heavy use are all examples of places that benefit from a gate system that doesn’t rely on a clear and level track.

They’re also often used in industrial or high-traffic settings. Their raised operation reduces wear and tear and keeps the mechanism clean and functional. Since very few of their moving parts are exposed to dirt and weather, they can also offer a particularly long service life.

The key differences between sliding gates and cantilever gates

At a glance:

Mechanism:

- Sliding gates need a ground track

- Cantilever gates do not use a ground track

Site suitability:

- Sliding gates suit flat, clean surfaces

- Cantilever gates work well on sloped, rough, or obstructed terrain

Space requirements:

- Sliding gates save internal space but require clear ground

- Cantilever gates need more lateral clearance for counterbalance

Maintenance:

- Sliding gates need regular clearing of the track

- Cantilever gates are less affected by dirt, snow or ground debris

Though both gate types serve the same function – secure, controlled access – the way they achieve it differs in several practical ways. Sliding gates use a ground-level track and roll open horizontally along a defined path. This design is simple and compact, but it depends entirely on the condition of the surface. That means that any unevenness, encroaching vegetation or build-up of debris can all potentially impact its ability to function. On the other hand, cantilever gates are suspended above ground and supported by a counterbalance mechanism, enabling them to glide across the entrance without touching the surface beneath.

This makes cantilever gates especially suitable for uneven terrain, gravel drives, snowy climates or any area where a smooth, clean track would be difficult to maintain. Sliding gates, while space-efficient, are better suited to solid, flat surfaces that can support a clean track without interruption.

Space around the entrance also plays a major role. Sliding gates are excellent when there’s only limited space behind the gate, as they move laterally along the fence line. However, they require a clear and level run across the gateway. Cantilever gates on the other hand need more space at the side due to the counterbalance section, which typically extends well beyond the width of the actual opening. This extra space is often more readily available on wider driveways or open commercial sites, and easily planned in.

When it comes to maintenance, sliding gates tend be slightly more maintenance-intensive – but only relatively. You can sometimes find leaves, mud or ice in the ground tracks, so it’s important to put in place a regular cleaning schedule for reliable operation. Cantilever gates avoid this issue entirely – with no ground-level components running across the opening, they stay cleaner and function more reliably in adverse conditions. (However, it’s still worth planning in a maintenance schedule for these too!)

Both types can be automated and integrated with modern access control systems, offering flexibility for remote entry, intercoms, keypads and safety features like motion sensors. Design preferences can be fully accommodated too, with either style available in traditional or contemporary wrought iron finishes, including decorative scrolls, finials and privacy features. The final decision usually comes down to the environment, available space, and how much day-to-day maintenance you’re prepared to manage.

And of course, if you ever need any help or advice on which gates to choose, that’s exactly where we can help here with North Valley Forge. If you need more advice on how to choose between these specific gates, we’d recommend checking out our post on how to choose between a swing or sliding wrought iron gate. Alternatively, if you’d like any more information about our range of beautiful wrought iron gates, you can request one of our brochures, make an inquiry, or give us a call on 01282 677300. A member of our friendly team will be more than happy to assist!

Menu

Menu